Use Case Scenarios

See how RapidOps fits different manufacturing environments—from micro sized to the largest manufacturing operations, without specialist IT or expensive hardware.

Use Case: Job Shop

This company requires a solution that can be configured without specialist IT support and used easily on the shop floor without disrupting existing workflows. RapidOps is configured and managed from a standard computer, laptop or tablet, allowing managers and planners to set up jobs, schedules, and processes quickly and easily. On the shop floor, operators access RapidOps using computers or tablet devices mounted at workstations or carried between operations. This provides real-time visibility of job status, priorities, and next tasks without the need for expensive industrial terminals or custom hardware.

Typical Setup

- Computer, laptop or tablet for system configuration and planning

- Computer or tablet devices on the shop floor for operator interaction

- No specialist hardware, PLC integration, or infrastructure changes required

Desktop Computer / Laptop (likely already existing or £150-500). Tablet with tough case (£150-300). This approach keeps deployment costs low, enables rapid rollout, and ensures the system fits naturally into day-to-day shop floor operations.

Problem

- Constant reprioritization

- No real-time WIP visibility

- Late jobs discovered too late

RapidOps Delivers

- Live job status

- Real-time bottleneck visibility

- Clear priorities for operators

Outcome

- Fewer production surprises

- Improved on-time delivery

- Better decision-making under changing conditions

Products Used

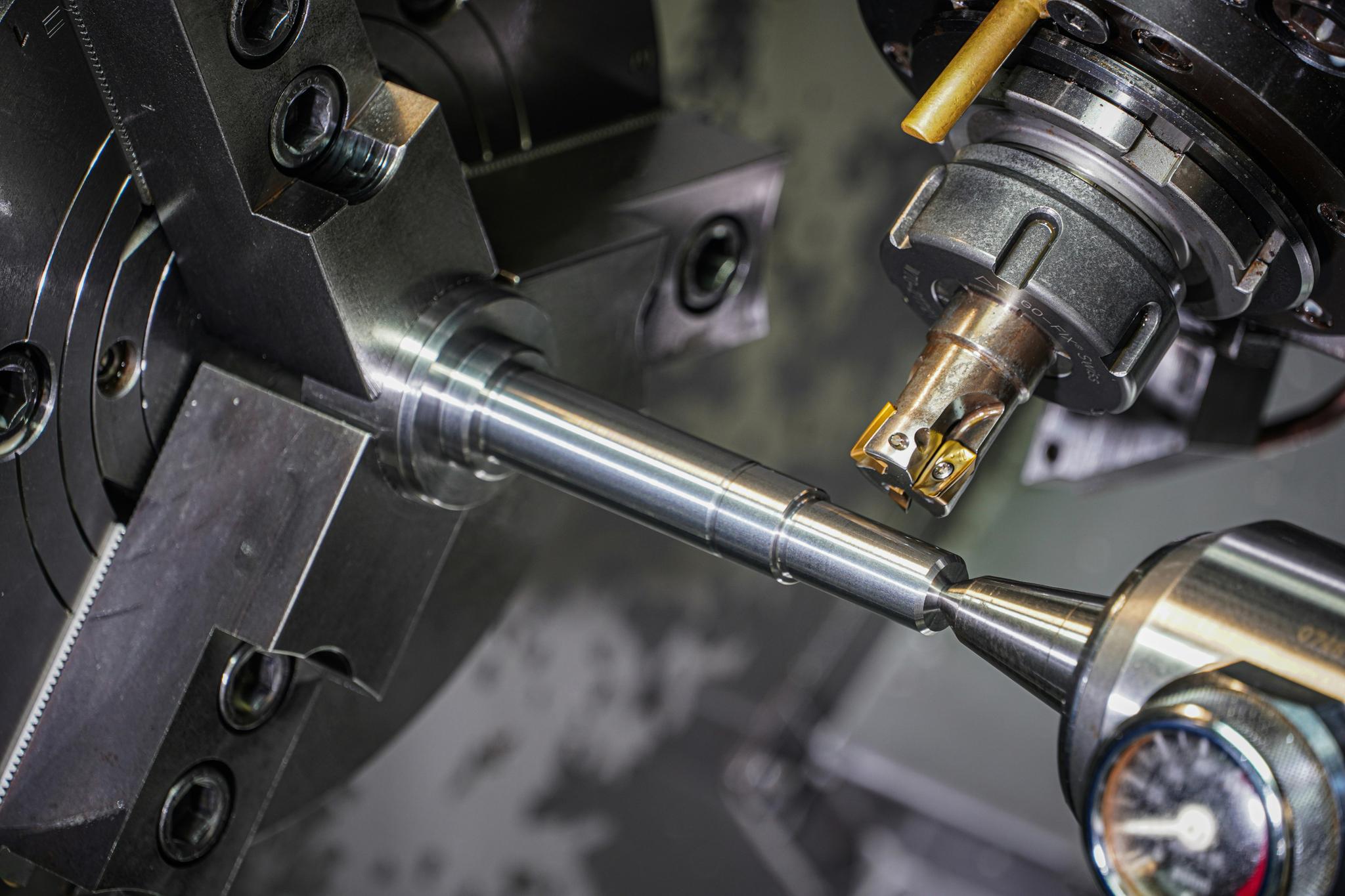

Use Case: Fabrication & Welding

This company specialises in fabrication and welding, producing custom metal components for multiple clients with varying specifications. Each job requires different materials, machines, and skilled operators, making coordination complex. Tracking progress is largely manual, using whiteboards, paper job cards, and verbal updates. Schedules often shift mid-day. Disconnects between material availability and labour assignments frequently cause delays. Without real-time insights, managers spend more time firefighting than proactively running the shop.

Typical Setup

- Computer or laptop for configuration and planning

- Tablet devices on the shop floor for operator access

- No industrial PCs or heavy IT investment required

RapidOps is configured from a computer, laptop or tablet, enabling managers to set up jobs, sequences, and priorities efficiently. On the shop floor, operators use iPads or tablets, either mounted at workstations or handheld, to view job progress, report task completion, and receive next-step instructions. This setup keeps costs low, deployment fast, and adoption intuitive for shop-floor teams.

Problem

- Manual tracking of jobs and materials

- Schedule chaos due to shifting priorities

- Disconnects between material availability and labour assignments

RapidOps Delivers

- Shop-floor production tracking

- Clear job progress and real-time status without paperwork

- Real-time material transactions and insights

Outcome

- Reduced unplanned work and schedule chaos

- Greater operational control

- Fewer missed deadlines and improved throughput

Products Used

Use Case: Electronics & Assembly

This company assembles electronic and electromechanical products in small to medium batch sizes for multiple customers. Production involves a high mix of products, frequent changeovers between jobs, and multiple assembly and test stations. As work moves between stations, visibility is often lost. Teams struggle to understand where jobs are queued, which stations are becoming bottlenecks and whether issues are impacting downstream operations. Without real-time insight, delays are discovered only after throughput has been affected.

Typical Setup

- Computer, laptop or tablet for configuration and planning

- Tablet devices at assembly and test stations

- Cloud-based deployment with no on-premise servers

RapidOps is configured and managed from a standard office computer or laptop, allowing planners and supervisors to define workflows, stations, and job sequences without specialist IT support or lengthy setup. On the shop floor, operators interact with RapidOps using tablet devices or computers, positioned at each assembly or test station. Because RapidOps is cloud-based and hardware-agnostic, deployment does not require industrial PCs, custom terminals, or complex integrations. Most sites can be up and running using existing hardware within days.

Problem

- High product mix with frequent changeovers

- Limited visibility between assembly and test stations

- Issues detected too late, causing downstream delays

RapidOps Delivers

- Station-level production tracking

- Clear, real-time job flow visibility across stations

- Faster detection of issues and bottlenecks

Outcome

- Faster throughput across the assembly line

- Fewer delays and handover issues

- Improved coordination between teams and stations

Products Used

Ready to Transform Your Manufacturing Operations?

Our team will help you identify the right RapidOps setup for your shop—no specialist IT or heavy hardware investment required.

Schedule a Demo